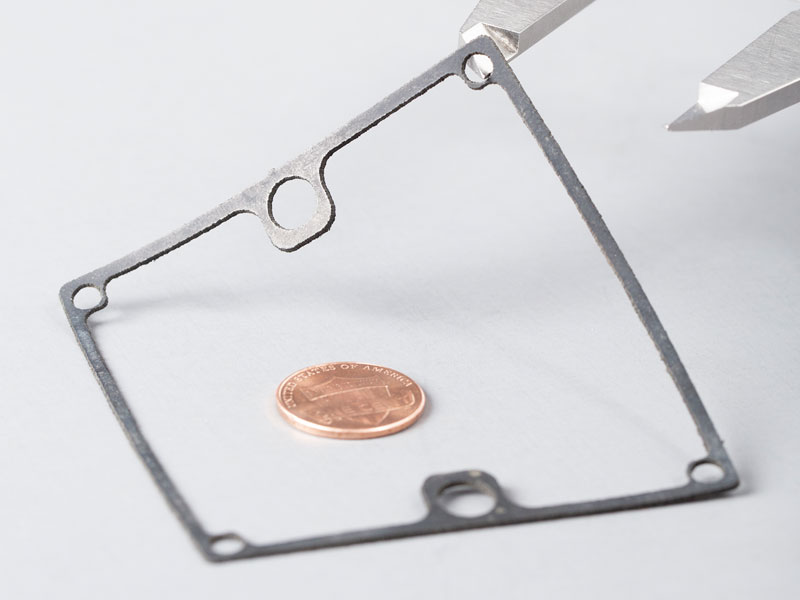

Precision Waterjet Cutting

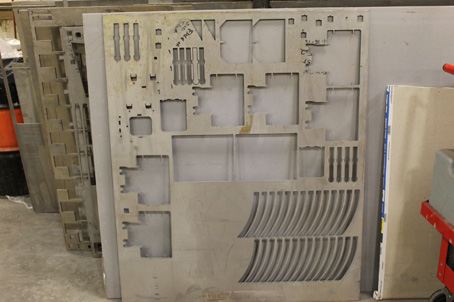

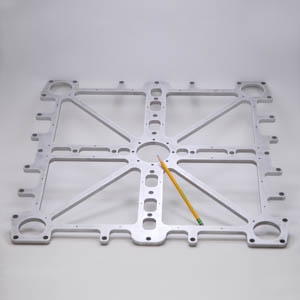

Versatile Cutting for Complex Materials & Thick Stock

Excell’s waterjet cutting services deliver clean, accurate cuts across a wide range of materials—including metals, plastics, composites, and even hardened materials—without introducing heat or distortion. Our OMAX 55100 systems are ideal for both prototyping and production work, especially where laser or traditional cutting methods fall short.

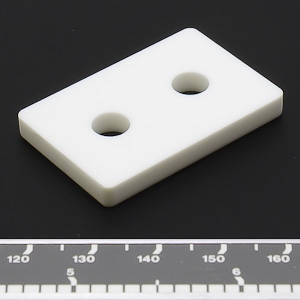

With cold cutting technology, we maintain material integrity, eliminate heat-affected zones, and handle delicate or thermally sensitive materials with precision.

Capabilities & Features

Machine Specs:

- OMAX 55100 Waterjets

- High-pressure abrasive and pure water cutting

- Cutting envelope up to 55″ × 100″+

Material Flexibility:

- We cut a wide range of materials including but not limited to:

- Mild and stainless steels

- Aluminum (all grades)

- Hardened tool steels

- Copper, brass, titanium

- G10, phenolic, and carbon fiber composites

- Ceramics and glass

- Rubber, foam, plastics, and laminates

Waterjet Tolerances & Kerf

- Standard tolerance: ±0.010″

- Tight tolerance capability: up to ±0.005″ (geometry dependent)

- Kerf width: typically 0.030″–0.045″, depending on material thickness and nozzle setup

- Clean edges, no heat distortion, minimal secondary finishing required

This cold-cutting process eliminates thermal stress, discoloration, and material warping, making it ideal for preserving material integrity. It excels at cutting thick, hard, brittle, or layered materials, and is equally effective for both one-off prototypes and full production volumes. With minimal fixturing and fast programming, waterjet cutting offers quick turnaround times. It’s also the perfect solution for materials that are reflective or otherwise challenging to cut with lasers.