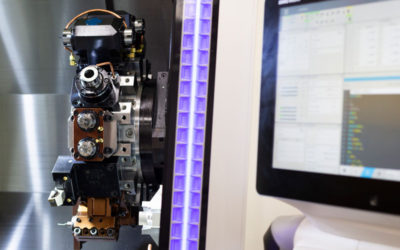

Turning / Turn Mill

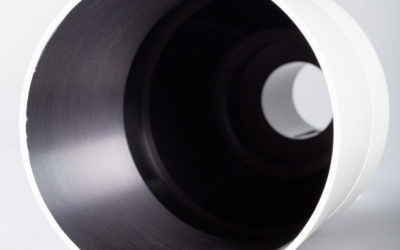

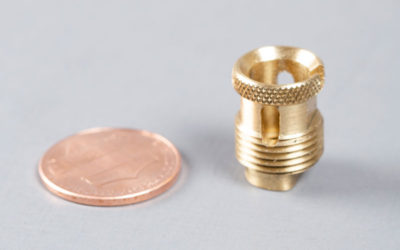

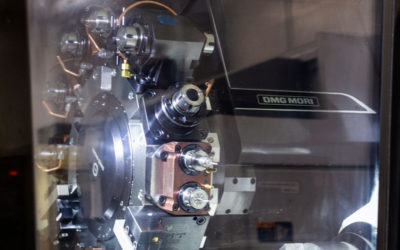

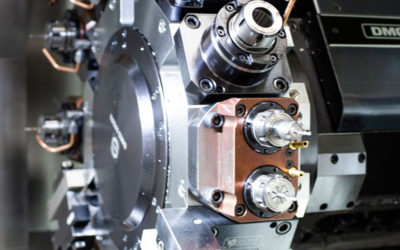

Our turning and turn-mill capabilities are built to give customers full design freedom without compromise. With advanced DMG MORI and MAZAK turn-mill centers, we produce complex, high-tolerance parts in a single setup—eliminating the risk of transfer-related errors and shortening lead times. Whether you’re ordering one part or a full production run, we offer unmatched flexibility in material choices and quantities.

Materials We Work With:

Metals (Included but not limited to)

- Aluminums

- Stainless steels

- Mild steel

- Alloy steels

- Tool steel

- Brass and copper alloys

- Titanium

- Tungsten

- Armor-grade alloys

Plastics (Included but not limited to)

- Delrin (Acetal)

- UHMW

- Nylon (including glass-filled variants)

- Polycarbonate

- PTFE (Teflon)

- ABS and PVC

- PEEK

Composites & Other Materials (Included but not limited to)

- G10/FR4 (glass-reinforced epoxy laminate)

- Phenolic laminates

- Machinable ceramics

- Acrylic

Machine Capacity/ Tolerancing

- Combined turning and milling in a single setup for enhanced precision

Machine Capacity/ Tolerancing

- Combined turning and milling in a single setup for enhanced precision

- Largest chuck diameter: 10”

- Turning tolerances: ±0.0005″ typical, tighter upon request

- Concentricity and roundness control within 0.0003″ depending on material/setup

Why Choose Our Turning Services?

We provide high-precision CNC turning tailored for complex parts, ensuring accuracy and reliability across a wide range of materials and sizes. Our capabilities are fully scalable, supporting both low-volume and high-volume production with ease. With rigid quality control processes in place, we guarantee part consistency from start to finish. Combined with expert programming and efficient setup, we deliver quick lead times to keep your projects on schedule.