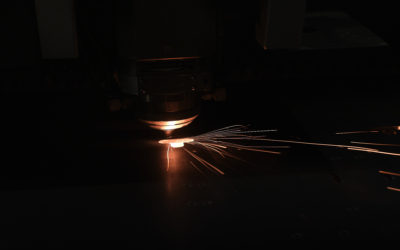

High-Speed Laser Cutting with Lights-Out Automation

High-Speed Laser Cutting with Lights-Out Automation

Precision. Speed. Repeatability.

Excell is proud to offer advanced laser cutting services powered by the AMADA ENSIS 3015 AJ 3kW fiber laser, paired with the AMS 3015 CL automated material handling system. This platform enables lights-out operation for continuous, unattended production—combining high-precision cutting with lean efficiency.

Whether you’re prototyping or scaling to high-volume production, this system ensures consistent part quality with short lead times, minimal human error, and full traceability.

System Highlights

- Exceptional edge quality on steel, stainless, and aluminum

- Capable of cutting intricate geometries and fine features

- Excellent performance on thin to mid-thickness materials

AMS 3015 CL Automation:

-

- Fully automated load/unload system for continuous production

- Supports high-volume jobs with minimal operator intervention

- Enables overnight and weekend lights-out cutting

Cutting Capabilities

- Mild Steel: up to 0.1.00″

- Stainless Steel: up to .500″

- Aluminum: up to 0.500

- Tolerances: typically held to ±0.005″, tighter on request

- Part nesting & material optimization to reduce scrap and cost

Why Excell for Laser Cutting?

Our services offer seamless integration with forming, machining, and welding, providing a streamlined solution for your fabrication needs. We specialize in producing brackets, panels, covers, chassis, and precision flat patterns with exceptional accuracy. With a wide range of materials stocked in-house, we ensure fast turnaround times to keep your projects moving. Additionally, our engineering team is available to support and refine your designs for optimal cutting performance and quality.