Mechanical Assembly & Fabrication Integration

From Individual Components to Complete Systems

Excell provides full-service mechanical assembly to streamline your supply chain and reduce project complexity. With machining, sheet metal, welding/ fab., hardware installation all in-house, we deliver precision-built assemblies that are ready to integrate—without juggling multiple vendors.

Whether you’re building prototype fixtures, box builds, or complex mechanical systems, our team ensures every component fits, functions, and ships as intended.

Welding Capabilities

TIG Welding:

- Precision welding for aluminum, stainless steel, and thin-gauge materials

- Ideal for high-quality cosmetic welds and small assemblies

MIG Welding:

- Faster, strong welds for structural parts and heavier-gauge metals

- Excellent for steel enclosures, brackets, frames, and large assemblies

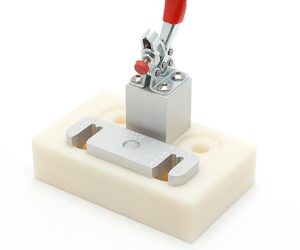

Hardware Installation & Assembly Services

- PEM® self-clinching fasteners (nuts, studs, standoffs)

- Captive panel screws, rivet nuts, spacers, and staked hardware

- Pop rivets, spring-loaded hardware, latches, grommets

- Thread-locking and sealing compounds where required

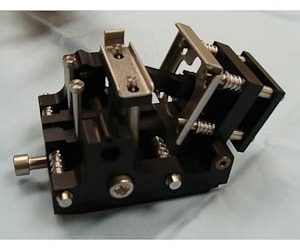

Sub-Assembly & Integration

From individual components to tested sub-systems we provide complete sub-assembly support:

- Chassis and enclosure builds

- Multi-part mechanical assemblies

- Bracket, panel, and hardware pre-kitting

- Testing, labeling, packaging, and delivery ready-to-use or ready-to-ship

We simplify your workflow by managing the entire process under one purchase order—from part fabrication to final assembly. This streamlined approach reduces lead times, minimizes handoffs, and lowers the risk of misalignment. Our in-house coordination of machining, forming, and welding ensures precise fits and seamless integration. With a strong focus on quality, we incorporate visual inspections and test-fit verification to deliver reliable, high-performance assemblies every time.